We love to make furniture that meets a need, realizes a vision, and lasts a lifetime. See what our process is like and how to have a custom piece of furniture designed and created for your home or business.

THE PROCESS

1. Choose your wood.

Choose from various shapes and sizes of our kiln-dried slabs.

2. Customize your project.

Customize dimensions, finish, base and everything in between.

3. Ready in up to 12 weeks.

Once designed we will have it ready for pickup within your project timeline.

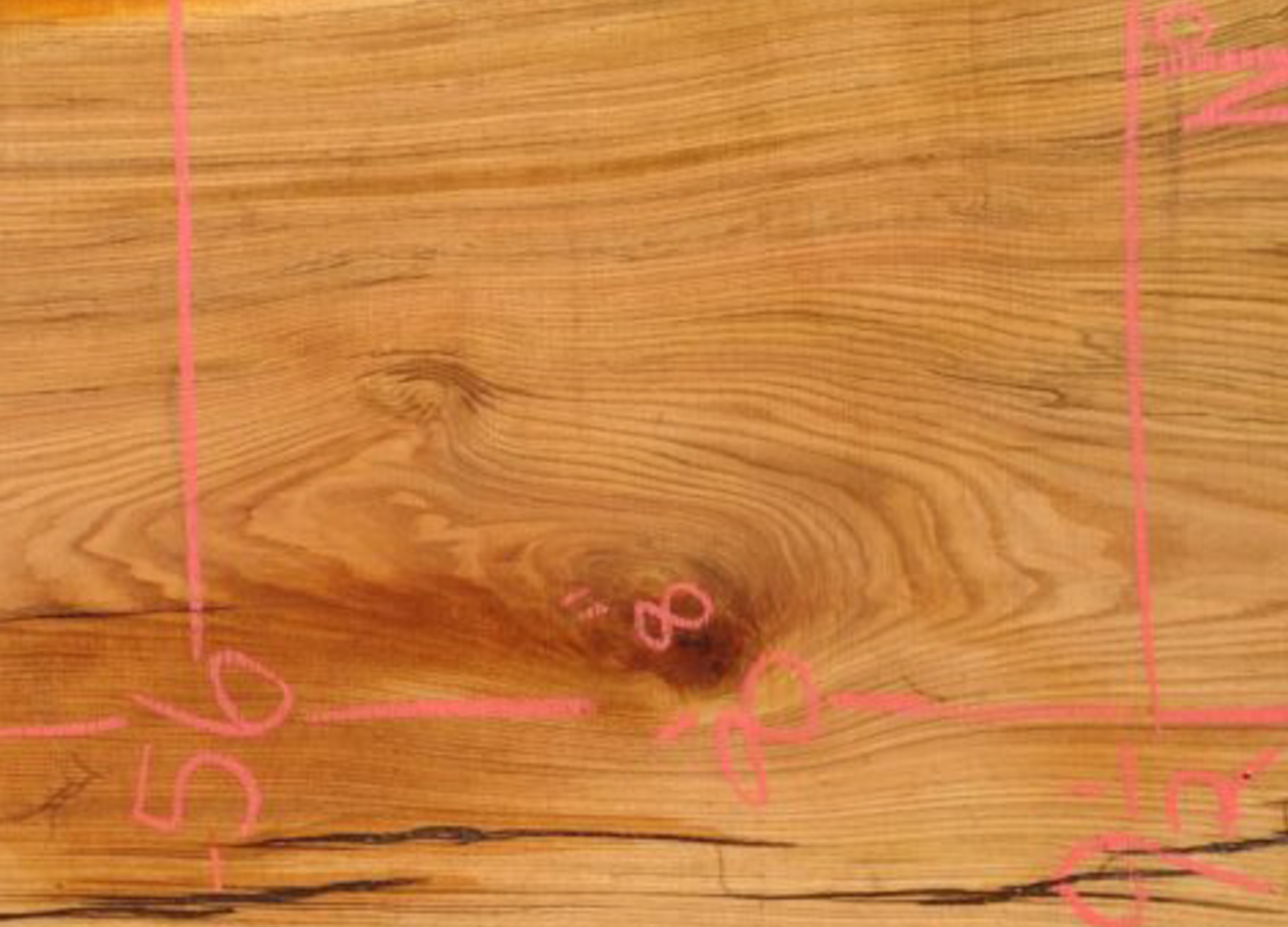

WOOD SPECIES

Our most commonly available live edge wood species are walnut, monkey pod, maple and white oak. Please use the pictures below as a reference only, as the actual color will vary between each individual slab. If live edge is not what you need we can also build your project with dimensional lumber. We commonly carry many domestic and exotic species in dimensional lumber including Ash, Hickory, White oak, Maple, Walnut, Sapele, Afromosia, and Brazilian Cherry.

Black Walnut

Hardness: 1010

Monkey Pod

Hardness: 900

Maple

Hardness: 950

White Oak

Hardness: 1360

Rosewood

Hardness: 1660

Camphor

Hardness: 950

Mahogany

Hardness: 800

Pin Oak

Hardness: 1500

BASES

We offer a variety of black steel bases. The most common requests are pictured below. We also build custom wood and metal bases upon request, depending on the details of the project.

U-Frame

X-Frame

A-Frame

Trapezoid Frame